Nell'industria farmaceutica, sempre più competitiva, l'efficienza della linea di produzione influisce direttamente sui costi operativi e sulla reattività al mercato di un'azienda. Essendo il punto di partenza del processo di confezionamento dei farmaci, le prestazioni dell'ordinatore di flaconi sono di fondamentale importanza.

Un ordinatore di flaconi efficiente e stabile garantisce che i flaconi siano orientati e trasportati rapidamente e con precisione alle operazioni successive, come il riempimento e la tappatura. È un'apparecchiatura chiave per eliminare i colli di bottiglia della produzione e ottenere una produzione automatizzata continua.

Ordinatore di flaconi: funzioni principali e tipologie

Lo scopo fondamentale e la varietà degli ordinatori di flaconi sono fondamentali per ottimizzare le fasi iniziali del confezionamento farmaceutico.

Funzione principale dell'ordinatore di flaconi

La funzione principale dell'ordinatore di flaconi è quella di organizzare, orientare e trasportare automaticamente e in modo continuo flaconi vuoti disorganizzati.

Sostituisce efficacemente il posizionamento manuale tradizionale dei flaconi, aumentando significativamente la continuità della linea di produzione. Questa automazione riduce drasticamente l'intervento umano, abbassando il rischio di errore umano e contaminazione, il che è fondamentale per soddisfare gli elevati standard di qualità richiesti nell'industria farmaceutica.

Tipologie comuni (classificazione in base al principio di funzionamento)

In base ai loro meccanismi operativi, i principali tipi di ordinatori di flaconi includono:

1. Ordinatore di flaconi centrifugo

Principio di funzionamento: utilizza la forza centrifuga generata da un disco rotante ad alta velocità per spingere i flaconi verso l'esterno contro la parete di contenimento. Con l'aiuto di una guida, i flaconi in posizione verticale vengono indirizzati all'uscita di scarico. I flaconi orientati in modo errato (sdraiati o con il collo verso il basso) ricadono nel disco a causa di un centro di gravità instabile e vengono ricircolati fino a quando non sono posizionati correttamente per lo scarico.

Vantaggi: velocità operativa molto elevata, efficienza eccezionale e alta capacità.

Svantaggi: provoca un impatto significativo, non adatto a contenitori fragili o in materiale morbido (ad esempio, alcuni flaconi in PET leggeri).

Applicazioni: utilizzato prevalentemente per l'ordinamento ad alta velocità di contenitori rotondi e resistenti per acqua, bevande, salsa di soia, aceto, ecc.

2. Ordinatore di flaconi a tavola rotante

Principio di funzionamento: i flaconi vengono alimentati su un disco o un tavolo grande e a rotazione lenta. Il perimetro è dotato di una guida esterna fissa. Mentre il disco ruota, i flaconi vengono delicatamente capovolti e riorientati attraverso il contatto con la guida. I flaconi in posizione verticale e correttamente orientati vengono guidati fuori dal disco nell'apposito canale di scarico, mentre gli altri rimangono in ricircolo per un ulteriore orientamento.

Vantaggi: movimentazione estremamente delicata, basso impatto e rumore, adatto a un'ampia varietà di forme di contenitori (tra cui quadrati, rettangolari, ovali).

Svantaggi: la produttività è generalmente inferiore rispetto ai modelli centrifughi.

Applicazioni: ideale per contenitori non rotondi, flaconi cosmetici, flaconi farmaceutici e contenitori in cui è necessario ridurre al minimo i graffi sulla superficie (ad esempio, flaconi in vetro o plastica di alta qualità).

3. Ordinatore di flaconi a nastro

Principio di funzionamento: impiega due nastri trasportatori paralleli che funzionano a velocità diverse. La conseguente differenza di attrito fa ruotare i contenitori. Questa rotazione, combinata con guide strategiche, orienta i flaconi, consentendo di selezionare quelli posizionati correttamente.

Vantaggi: meccanicamente semplice, offre flessibilità per applicazioni personalizzate.

Svantaggi: efficienza e capacità moderate; la gamma di applicazioni è limitata a specifici tipi di contenitori.

Applicazioni: utilizzato principalmente in linee di produzione personalizzate o non standard per la gestione di forme di contenitori uniche o difficili.

efficiente

La scelta dell'ordinatore di flaconi giusto richiede una valutazione multidimensionale per garantire che l'apparecchiatura migliori effettivamente la velocità e l'efficienza della linea di produzione. I principali fattori di selezione sono dettagliati di seguito:

1. Capacità di produzione (flaconi/minuto - BPM)

Questo è l'indicatore più cruciale. La capacità massima dell'ordinatore scelto deve essere superiore o uguale alla velocità progettata dell'intera linea di produzione. Inoltre, è necessario considerare una capacità di riserva dal 10% al 20% per gestire le richieste di produzione di picco, garantendo che l'ordinatore non diventi il collo di bottiglia della produzione.

2. Adattabilità al tipo di flacone

È necessario definire chiaramente le proprie esigenze di produzione: si utilizzerà un singolo tipo di flacone a lungo termine o sono necessari cambi frequenti tra diversi formati?

- Apparecchiature dedicate a formato singolo: in genere offrono una maggiore efficienza e una struttura più semplice.

- Apparecchiature compatibili con più formati: offrono flessibilità adattandosi a vari flaconi tramite la sostituzione di moduli o la regolazione dei parametri. Sebbene offrano una migliore versatilità, possono comportare investimenti iniziali e manutenzione più complessi.

3. Affidabilità e stabilità

I tempi di inattività della linea di produzione si traducono in perdite significative. Pertanto, l'ordinatore deve mostrare un tasso di guasto e di inattività estremamente basso. Scegliere apparecchiature di marchi rinomati e assicurarsi che i componenti critici (come sensori e motori) provengano da produttori noti. Questo approccio è essenziale per garantire la stabilità operativa a lungo termine.

4. Automazione e funzioni intelligenti

Gli ordinatori moderni dovrebbero integrare funzionalità avanzate:

- Rilevamento avanzato tramite sensori: funzioni come il rilevamento di flaconi mancanti o ribaltati.

- Allarmi e diagnostica automatica dei guasti: sistemi che individuano rapidamente i problemi.

- Sistema di controllo PLC: un controllore logico programmabile per un funzionamento preciso e integrato.

Queste funzioni intelligenti consentono una rapida identificazione dei problemi, riducendo significativamente i tempi di risoluzione dei problemi e aumentando l'OEE (Overall Equipment Effectiveness) complessivo.

5. Facilità di manutenzione e praticità di pulizia

La conformità agli standard GMP (Good Manufacturing Practice) è obbligatoria nel settore farmaceutico. Il design dell'apparecchiatura dovrebbe:

- Essere privo di angoli morti igienici.

- Avere parti a contatto facili da smontare e pulire (idealmente adatte per CIP/SIP - Clean-in-Place/Sterilization-in-Place).

Una struttura meccanica semplice e chiare linee guida per la manutenzione ridurranno notevolmente la difficoltà e il tempo dedicato alla manutenzione ordinaria.

6. Utilizzo di energia e spazio

- Il design compatto riduce al minimo lo spazio necessario, ottimizzando la disposizione dell'officina.

- Sistemi di azionamento ad alta efficienza e design a risparmio energetico contribuiscono a ridurre il consumo energetico a lungo termine, il che è fondamentale per il controllo dei costi operativi.

Come valutare un fornitore di ordinatori di flaconi

Scegliere buone apparecchiature significa anche scegliere un buon partner.

Criteri chiave per la valutazione di un fornitore di ordinatori di flaconi

Supporto tecnico e servizio post-vendita: indagare i tempi di risposta del fornitore, la professionalità del suo team di supporto tecnico e la sua capacità di fornitura di pezzi di ricambio.

Casi studio di clienti ed esperienza di successo: chiedere casi studio di successo nello stesso settore o con applicazioni simili; questa è la prova più diretta delle prestazioni dell'apparecchiatura.

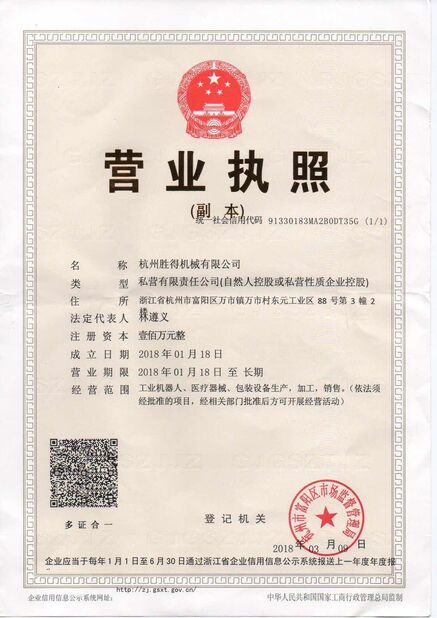

Certificazioni e qualifiche: assicurarsi che il fornitore disponga della certificazione del sistema di gestione della qualità ISO 9001, che le sue apparecchiature siano conformi agli standard di sicurezza CE e che il design e i materiali soddisfino i requisiti GMP.

Capacità di personalizzazione: se i tipi di flaconi o i processi presentano requisiti specifici, la capacità del fornitore di fornire uno sviluppo personalizzato è essenziale.

Strategie pratiche per migliorare l'efficienza della linea di produzione farmaceutica

Oltre a selezionare l'apparecchiatura giusta, è possibile aumentare ulteriormente l'efficienza della produzione attraverso le seguenti strategie:Ottimizzare la disposizione della linea di produzione: garantire una connessione fluida tra l'ordinatore di flaconi, la riempitrice e la tappatrice

per ridurre al minimo la distanza che i flaconi devono percorrere.

Manutenzione e calibrazione regolari: mantenere la vasca vibrante, le guide e i sensori puliti e calibrati con precisione per evitare tempi di inattività ed errori operativi.

Ottimizzare i parametri operativi: regolare l'intensità delle vibrazioni, la velocità del trasportatore e l'angolo di orientamento in base ai diversi tipi di flaconi per ottenere il miglior flusso e fluidità possibili.

Conclusione

Sebbene l'ordinatore di flaconi possa essere un piccolo componente, è il dispositivo "a gola" che guida il funzionamento efficiente e stabile dell'intera linea di confezionamento farmaceutico. Un processo di selezione ben informato e scientifico fa molto di più che aumentare immediatamente la velocità della linea di produzione; fornisce all'azienda stabilità di produzione a lungo termine e significativi risparmi sui costi.Se si desidera ottenere informazioni più dettagliate sui prodotti, organizzare test sulle apparecchiature o consultare una soluzione personalizzata, non esitare a contattarci

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!